Spiral Submerged Arc Welded Pipe SSAW

Carbon steel pipes are made from perforated steel ingots or solid round steel, and then hot

rolled, cold rolled, or cold drawn.

Commonly used materials include A53/A106/API Spec5L/A179/A213//A335/SSAW etc.

Details

Carbon Steel Pipe:

Carbon steel pipes are made from perforated steel ingots or solid round steel, and then hot

rolled, cold rolled, or cold drawn.

Commonly used materials include A53/A106/API Spec5L/A179/A213//A335/SSAW etc.

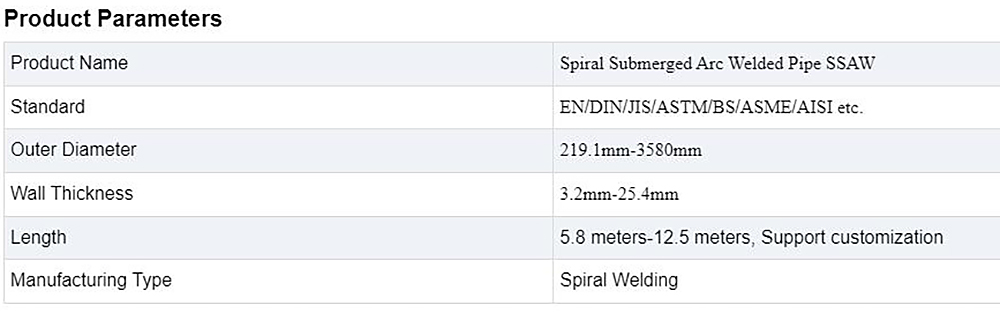

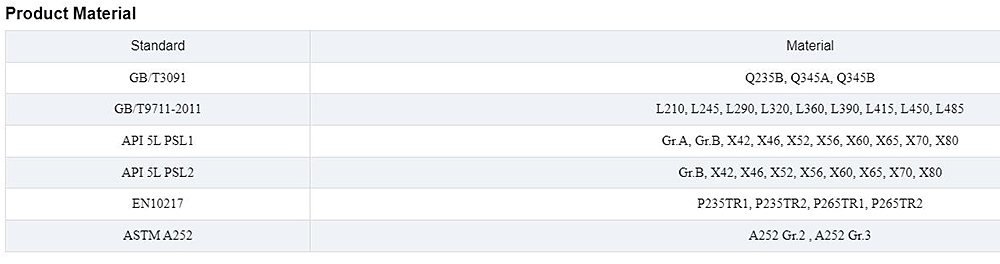

Spiral Submerged Arc Welded Pipe SSAW

The spiral submerged arc welded pipe is made of hot-rolled steel strip through constant temperature spiral forming and automatic submerged arc welding. The manufacturing process is to roll the steel strip, make the rolling direction at a certain angle to the center direction of the tube, and then form and weld, so the weld is spiral.

Spiral Submerged Arc Welded Pipe SSAW Description

Submerged arc welding is an important welding method. Its inherent advantages include stable welding quality, high welding productivity, no arc light and little smoke, making it an ideal choice in the production of important steel structures such as pressure vessels, pipe section manufacturing, box beam and column manufacturing. The strength of SSAW spiral welded pipes is generally higher than that of straight seam welded pipes. Welded pipes with larger diameters can be produced from narrower billets, and welded pipes with different diameters can also be produced from billets of the same width.

Scope of Application

Petroleum and natural gas industry, chemical industry, power industry, flammable liquid and incombustible liquid pipeline and building structure, water supply and drainage engineering, urban construction.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)