SPCC/SPCC/SPCD/SPCE Cold Rolled Steel Coil

Carbon steel coil mainly refers to steel with a carbon mass fraction less than 2.11% and without special added alloying elements.

Commonly used materials include A36/S235JR/A283/A514/A572/S355JR/A709/A285/A387/A515 etc.

Details

Carbon Steel Coil:

Carbon steel coil mainly refers to steel with a carbon mass fraction less than 2.11% and without special added alloying elements.

Commonly used materials include A36/S235JR/A283/A514/A572/S355JR/A709/A285/A387/A515 etc.

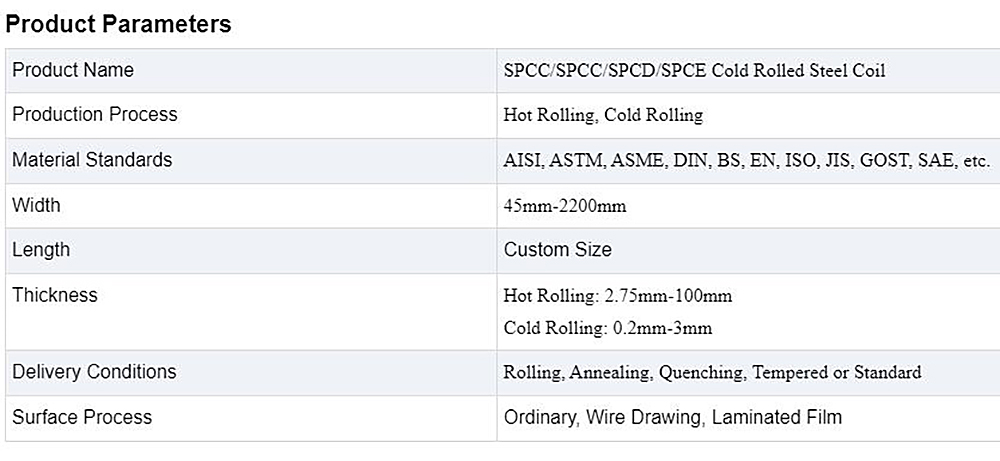

SPCC/SPCC/SPCD/SPCE Cold Rolled Steel Coil

SPCC steel is produced by subjecting hot rolled steel to a cold rolling process, which not only improves its surface finish but also enhances its mechanical properties.

SPCC/SPCC/SPCD/SPCE Cold Rolled Steel Coil

SPCC steel coil comes with impressive properties, making it an ideal choice across various industries. A key advantage is its high tensile strength, giving it the capacity to deal with heavy loads and resist deformation. So SPCC steel coil is especially suitable for applications requiring superior durability and structural integrity. Another notable feature of SPCC steel coil is its excellent formability as the coil can be easily shaped and molded into different sizes and dimensions without compromising its structural integrity. This flexibility makes it suitable for manufacturing processes like stamping, bending and deep drawing. SPCC steel coils have a uniform appearance that adds a professional feel to finished products using this material. Additionally, this surface helps greatly in preventing corrosion, thus extending the life of the coils.

Scope of Application

SPCC/SPCCT: Common & General Use; Characteristics: Suitable for bending processing and simple deep drawing processing, is the most demand varieties; Applications: Refrigerators, rails, switchboards, iron baskets and so on.

SPCD: Drawing & Stamping Use; Characteristics: Second only to SPCE, is the quality of the smaller deviation of the drawing steel plate; Applications: Automobile chassis, roof and so on.

SPCE/SPCF: Deep Drawing & Stamping Use; Characteristics: Grain is adjusted, deep drawing performance is excellent, after the stamping can get a beautiful surface. Applications: Car fender, rear side panels and so on.

SPCG: Extra-Deep Drawing & Stamping & Punching Use; Characteristics: Very low carbon cold rolled steel, excellent deep drawing processability. Applications: Car interior board, surface and so on.

Remarks: SPCCT is users specified the grade of SPCC which need to ensure that the tensile strength and extensibility of the species. SPCF, SPCG will need to ensure that there have non-aging (not due to the occurrence of tensile deformation of the property), after outside factory for 6 months – that is, SPCC, SPCD, SPCE if stored for a long time, will produce mechanical performance changes, especially to reduce the cold stamping performance, it should be used as soon as possible.SPCC series catalog need to make provision for hardness and surface in advance when ordering.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)