Prepainted Galvanized Steel Sheet

When steel components are used to make more complex finished products, they can be galvanized before the product is assembled. This is called pre-galvanizing, or "pre-galvanizing". It may also be referred to as "in-line", "continuous" or "rolled" galvanizing.

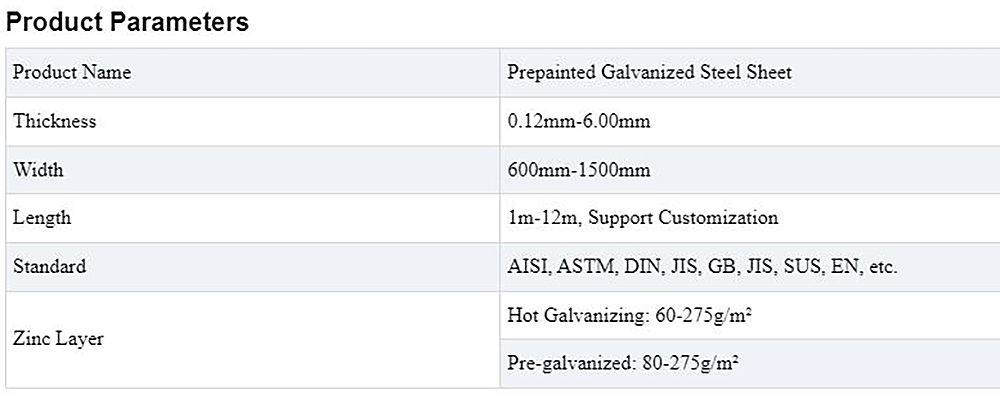

Details

Galvanized Steel Sheet:

Galvanized steel plate is coated with a layer of metal zinc to prevent corrosion on the surface of the steel plate and extend its service life. It is divided into hot-dip galvanizing and electrogalvanizing.

Prepainted Galvanized Steel Sheet

Galvanized steel plate is coated with a layer of metal zinc to prevent corrosion on the surface of the steel plate and extend its service life. It is divided into hot-dip galvanizing and electrogalvanizing.

Prepainted Galvanized Steel Sheet Description

Steel components (such as sheets or wires) are galvanized using an automated process before they are cut to size. This automated process will vary depending on the type of galvanized part. In general, steel components are immersed in a "galvanizing bath" of molten zinc for a short period of time. After the steel is removed from the bath, excess zinc is removed using a mechanical wiper, air knife, or steam. This leaves a relatively thin layer of galvanizing.

Scope of Application

Building Materials Field

Electrogalvanizing has a wide range of applications in the field of building materials. First of all, electro-galvanizing can be used to manufacture construction steel, which not only prevents metal oxidation and prolongs its service life, but also enhances the toughness, strength and corrosion resistance of steel, and improves the performance of steel. Secondly, in the decoration of building exterior walls, electro-galvanized aluminum alloy, electro-galvanized iron alloy and other materials are also widely used, which can protect the steel structure and prevent oxidation, but also has the characteristics of beauty and fire prevention.

Automobile Manufacturing Field

Electrogalvanizing is also a commonly used material in the field of automobile manufacturing. Electro-galvanized coating can be used for surface protection and repair of automobile parts to avoid oxidation corrosion and damage, and to improve the service life of automobiles. The electro-galvanized coating can also be used in the manufacture of parts such as car frames and casings to avoid oxidation and corrosion, and improve the overall quality and durability of the car.

Home Appliance Manufacturing Field

In the field of home appliance manufacturing, galvanizing also has its important applications. For example, the manufacture of refrigerators, washing machines and other household appliances shell, lining, refrigerator and other parts, usually need to use electro-galvanized material for surface coating, to prevent metal oxidation, improve appearance and performance.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)