Prepainted Galvanized Steel PPGI Coil

PPGI (Pre-Painted Galvanized Iron) steel coil is a high-quality metal material widely used in construction and industrial applications. It is typically cold-rolled or hot-rolled steel that undergoes galvanization and is coated with one or multiple layers of colorful paint.

Details

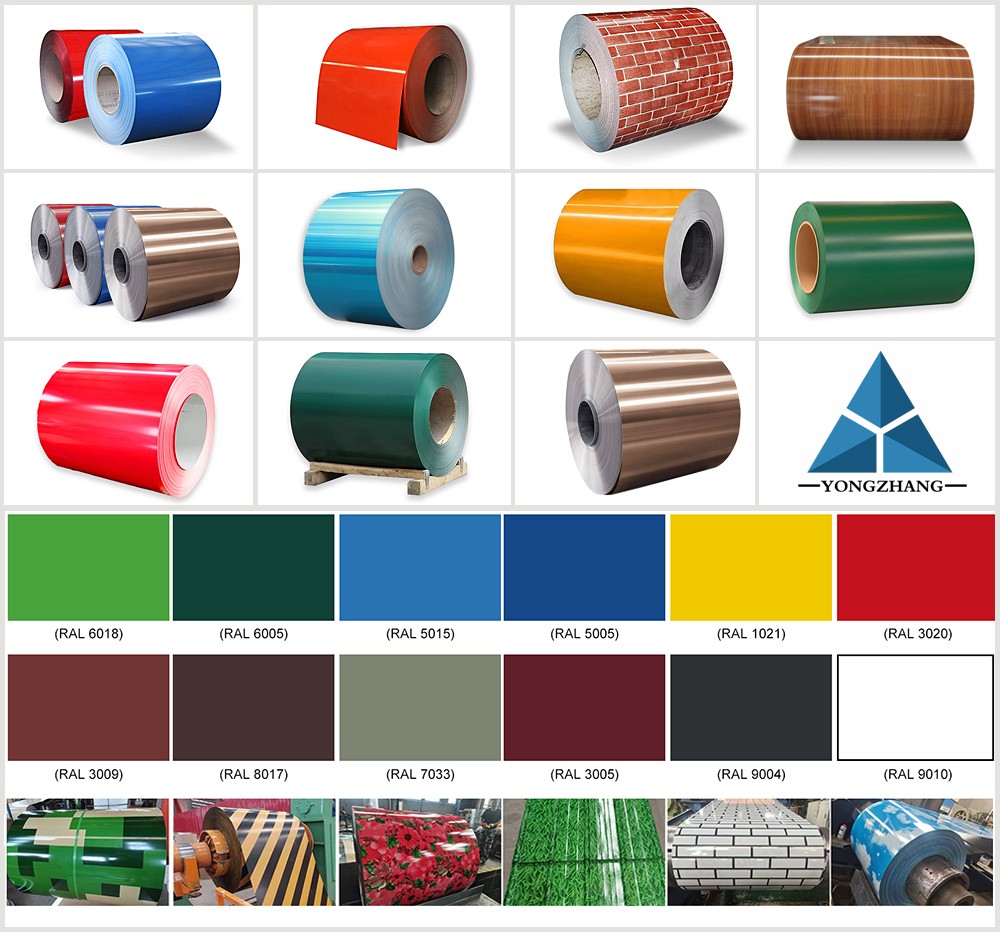

Color Coated Coil:

Color coated rolls are lightweight, aesthetically pleasing, and have good corrosion resistance.They can also be directly processed and are generally classified into gray white, navy blue, brick red, and other colors.

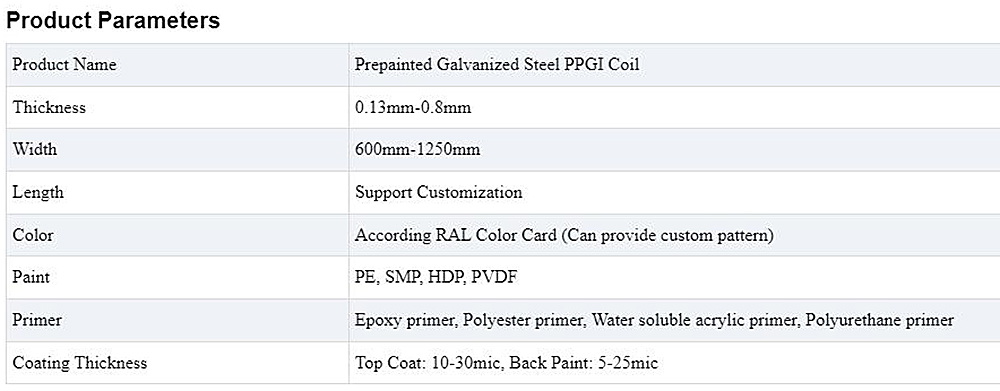

Prepainted Galvanized Steel PPGI Coil

PPGI (Pre-Painted Galvanized Iron) steel coil is a high-quality metal material widely used in construction and industrial applications. It is typically cold-rolled or hot-rolled steel that undergoes galvanization and is coated with one or multiple layers of colorful paint.

Prepainted Galvanized Steel PPGI Coil Description

Color coated coil can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc. Used for roof panels, wall panels, furniture, household appliances, auto parts, etc, it maintains the strength of galvanized steel, while its organic coating provides a variety of colors and attractive appearance.

Hot Dip Galvanized PPGI Steel

Mainly use hot-dip galvanized steel sheet as the substrate, due to the protection of zinc layer and organic coating, its service life is longer than hot-dip galvanized sheet. The available zinc layer is 275g/m2.

Electro-galvanized PPGI Steel

An electrogalvanized sheet was used as the substrate. Because the zinc layer of electrogalvanized sheet is thin, usually 20g/㎡, its corrosion resistance is not as good as that of hot-dip galvanized sheet. Therefore, the product is not suitable for making outdoor walls and roofs. But it has a beautiful appearance and excellent processing performance, mainly used for home appliances, steel furniture, interior decoration, etc.

PPGI Color Coating Coil Advantages

Color coated galvanized coil has a variety of colors and patterns to meet different styles and uses. The colorful coating also makes PPGI steel more resistant to corrosion and durable. PPGI steel coil has excellent processing performance. So you can make the coil into different products according to your needs. The color coated galvanized steel coil also retains the strength of the steel, making it tough and safe. The PPGI coated coil is light in weight and easy to transport and install. Compared with PPGL steel, the price is more affordable.

Surface Treatment

Laminated Film

The process is to coat a transparent organic film (30-50 µm) on the steel coil at high temperature. It has some unique properties, such as fire resistance, fingerprint resistance, excellent durability, anti-fouling ability, etc. Obviously, this treatment method can protect the steel coil well during storage and transportation.

Embossing

Embossed PPGI steel coil design has different patterns. Popular patterns are stucco, rhombus, etc. And it's customizable. Compared with the smooth steel coil, it has a vivid 3D effect.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester SMP

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Scope of Application

Construction industry: such as roof, interior and exterior wall panels, balcony panels, suspended ceilings, partition walls, windows, door panels, etc.

Transportation: For example, car trim panels, train or ship decks, containers, etc.

Electrical equipment: mainly used for making freezers, washing machines, air conditioners and other enclosures. PPGI coils for home appliances have the best quality and the highest production requirements.

Furniture:such as wardrobes, lockers, radiators, lampshades, tables, beds, bookcases, shelves, etc.

Other industries: such as roller shutters, billboards, traffic signs, elevators, whiteboards, etc.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)