Color Coated Galvanized Steel Sheet PPGI

Color-coated galvanized sheet PPGI uses hot-dip galvanized sheet, electro-galvanized sheet as the substrate. It is coated with one or more layers of liquid coating after surface pretreatment and roller coating method. After baking and cooling, the surface has good weather resistance, superior processing performance and is rich in colors.

Details

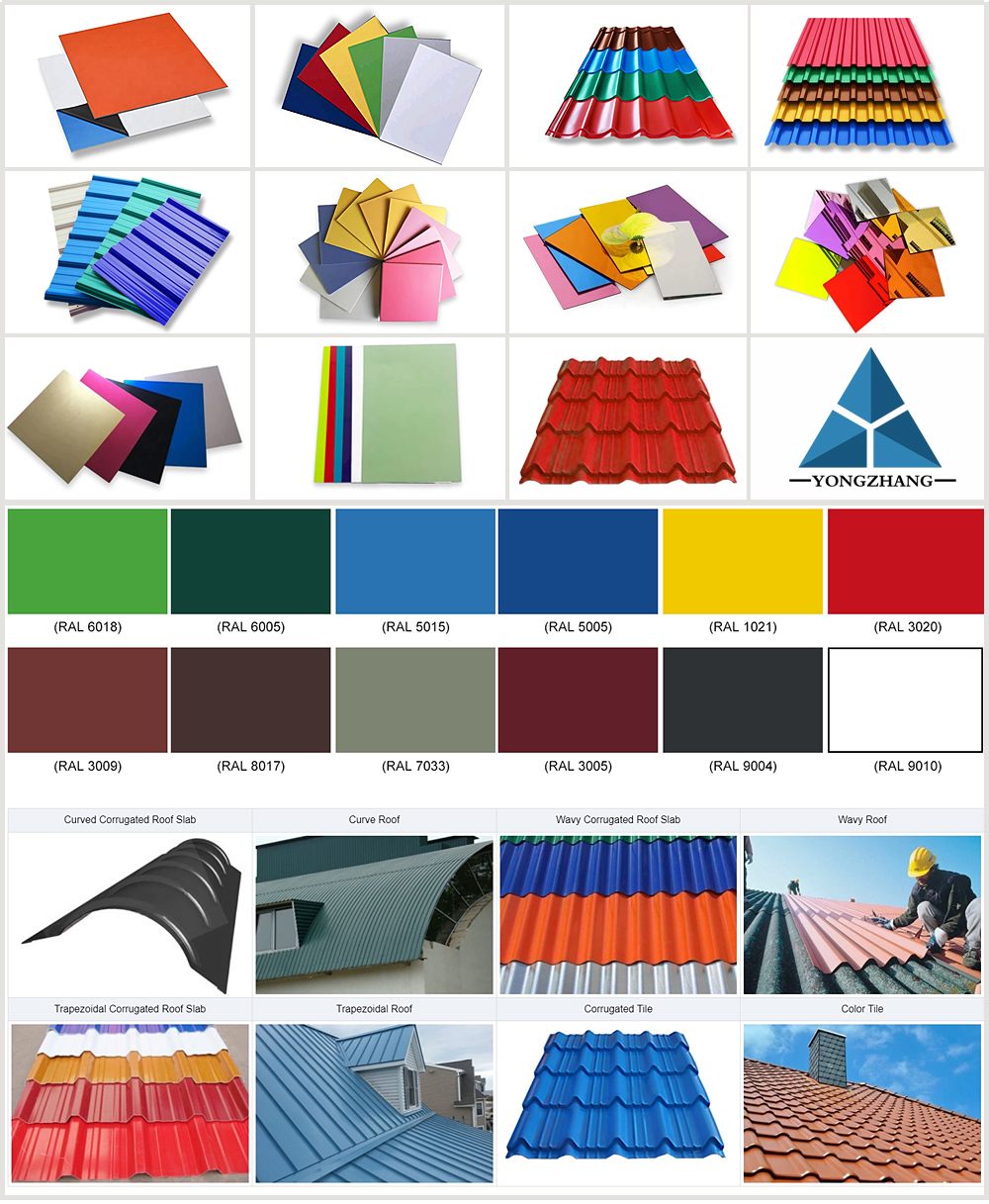

Color Coated Plate:

Color coated board is made from metal sheets as the substrate, coated or laminated with various organic coatings or plastic films on the surface, and can be divided into PPGl and PPGL.

Color Coated Galvanized Steel Sheet PPGI

Color-coated galvanized sheet PPGI uses hot-dip galvanized sheet, electro-galvanized sheet as the substrate. It is coated with one or more layers of liquid coating after surface pretreatment and roller coating method. After baking and cooling, the surface has good weather resistance, superior processing performance and is rich in colors.

Color Coated Galvanized Steel Sheet PPGI Description

Color coated board can be divided into ordinary PE, high corrosion resistant HDP, high corrosion resistant silicon modified polyester SMP, high corrosion resistant fluorocarbon PVDF, super corrosion resistant nano fluorocarbon PVDF, aluminum magnesium manganese color coated board, printing color coated board, etc.

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries.

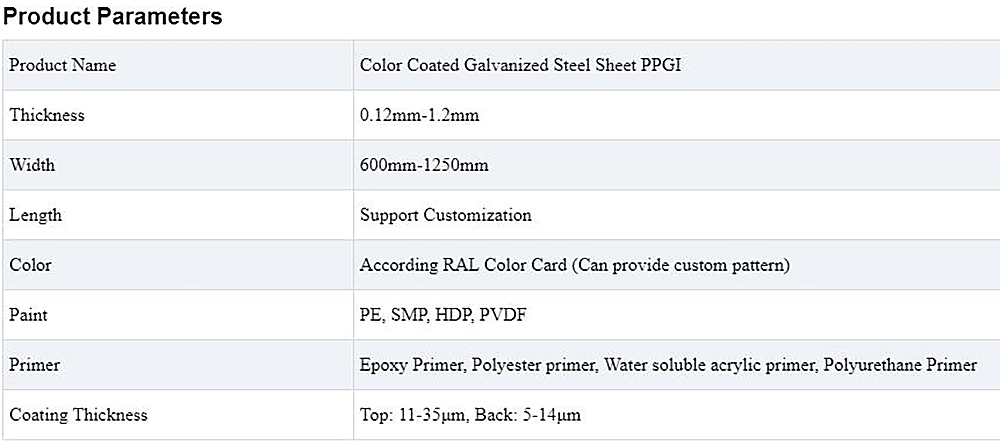

Color Selection

We provide many colors to choose from, the following are common colors, if you like other colors or patterns, please send us the RAL color code.

Advantages of Color Coated Plate

Custom Colors

You can choose any RAL color, as well as customize the pattern according to your needs. The beautiful surface makes the color coated board decorative. So it can be directly used in many fields.

Tough Soating

Color coated steel plate including PPGL plate PPGI steel, the use of continuous coil coating, the surface luster bright, no cracking, no peeling. In addition, it can keep the color for at least 10 years.

Excellent Mechanical Properties

The color coated plate retains the mechanical properties of the base metal, such as tensile strength. In addition, the application of the coating can protect the surface from rust, thereby extending its service life. Studies have shown that the service life of color-coated steel sheets is 50% longer than that of galvanized steel sheets.

Easy to Use

Different from the coil, the color coated plate is a kind of finished product. This means that it can be directly used in many industries. Considering its light weight, it is easy to carry and install. In addition, due to its aesthetic appearance, no additional decoration is required. Also, less maintenance is required during the service life.

Coating Type

In the coil coating, the durability of the role is the resin and pigment, the most commonly used finish polyester, silicon modified polyester, high durability polyester and polyvinylidene fluoride.

Polyester PE

Good adhesion, rich color, wide range in formability and outdoor durability, medium chemical resistance, low cost.

Silicon Modified Polyester SMP

The hardness, abrasion resistance and heat resistance of the coating film are good; as well as good external durability and powder resistance, gloss retention, general flexibility and medium cost.

High Durability Polyester HDP

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, good film adhesion, rich color, excellent cost performance.

Polyvinylidene Fluoride PVDF

Excellent color retention and UV resistance, excellent outdoor durability and chalking resistance, excellent solvent resistance, good formability, dirt resistance, limited color, and high cost.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)