AZ55 Galvalume Steel Coil

AZ55 is the standard for galvanized steel sheets and coils used in a variety of applications, including roofing and siding. The AZ55 name refers to the thickness of the coating on the coil, which is between 0.375 and 1.5mm (0.015 and 0.059 inches).

Details

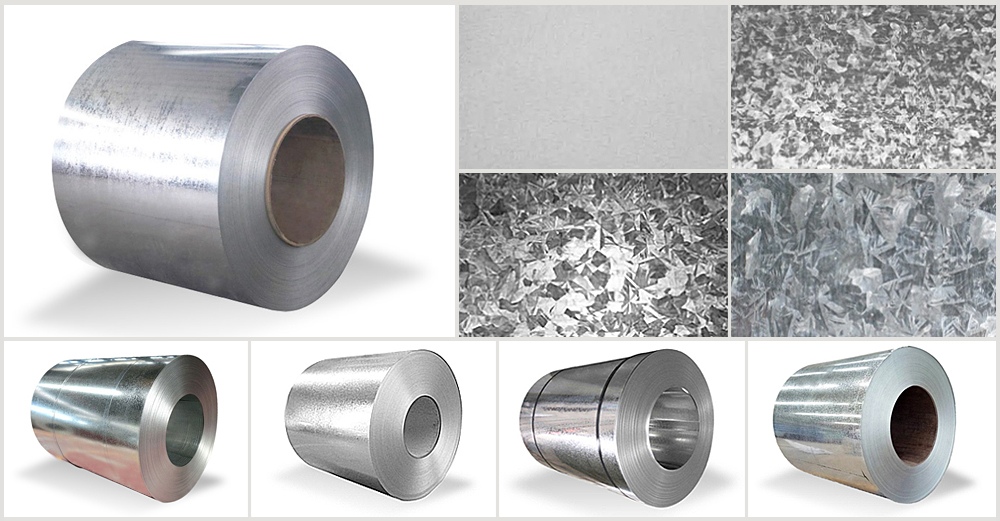

Galvalume Steel Coil:

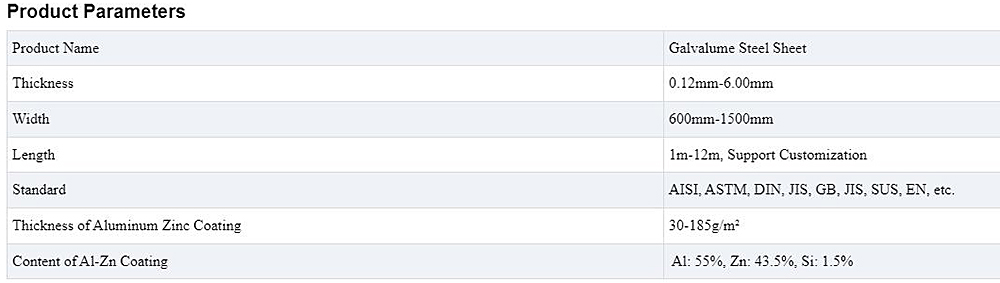

The coating composition of aluminum coated zinc coils is composed of 55% aluminum,43.4% zinc, and 1.6% silicon in weight ratio, respectively. Aluminum zinc coated steel coils can prevent long-term rusting of the steel coils.

AZ55 Galvalume Steel Coil

AZ55 is the standard for galvanized steel sheets and coils used in a variety of applications, including roofing and siding. The AZ55 name refers to the thickness of the coating on the coil, which is between 0.375 and 1.5mm (0.015 and 0.059 inches).

AZ55 Galvalume Steel Coil Description

AZ55 galvalume steel coil is coated with 55% aluminum zinc alloy by hot dip plating process. It has excellent corrosion resistance and can be used in various applications, such as the automotive industry, shipbuilding industry, construction industry, etc. In addition to being an excellent outdoor material, AZ55 galvalume steel coil also has many other advantages. For example, it can be used for electrical equipment manufacturing or decoration, such as fences. In addition to these uses, this steel can also be used in various industrial applications because of its good mechanical properties and corrosion resistance.

The production process of aluminum zinc plating is as follows:

Uncoiling-cleaning-annealing-zinc pot-cooling-air knife-straightening-post-treatment-coiling

Heat Reflection

People use it as a thermal insulation material, and its thermal reflectivity is up to twice that of galvanized steel.

Heat Resistance

Galvanized steel coil has good heat resistance and can withstand high temperatures above 300°C, which is very similar to the oxidation resistance of aluminized steel at high temperatures. Commonly used in chimney tubes, ovens, illuminators, fluorescent lampshades, etc.

Corrosion Resistance

The key to the corrosion resistance of aluminized zinc steel coil is the protective performance of aluminum. Once the zinc is worn, the aluminum forms a dense layer of aluminum oxide, preventing further internal corrosion.

Economy

The density of 55% AL-Zn is smaller than that of Zn. Therefore, when the coating weight and thickness are the same, the area of the aluminum-zinc plated steel sheet is 3% larger than that of the galvanized steel sheet.

Easy to Paint

The coating material on the aluminized zinc steel plate has excellent adhesion, and can be directly coated with tar on advertising boards and common plates without pretreatment such as weathering.

Scope of Application

Construction industry: such as roof, internal and external wall panels, sound insulation walls, pipes, garages, etc.

Automotive industry: such as mufflers, exhaust pipes, wiper accessories, fuel tanks, truck containers, etc.

Household appliances: such as refrigerator backplane, air conditioner, microwave oven, LED backlight, electric cabinet, etc

Agricultural use: such as greenhouse, granary, pig farm, chicken coop, etc

Other industries: such as heat exchangers, dryers, etc.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)