A204 Pressure Vessel Steel Plate

Carbon steel plate mainly refers to steel with acarbon mass fraction less than 2.11% and without special added alloy elements.

Commonly used materials includeA36/S235JR/A283/A514/A572/S355JR/A709/A285/A387/A515 etc.

Details

Carbon Steel Plate

Carbon steel plate mainly refers to steel with acarbon mass fraction less than 2.11% and without special added alloy elements.

Commonly used materials

includeA36/S235JR/A283/A514/A572/S355JR/A709/A285/A387/A515 etc.

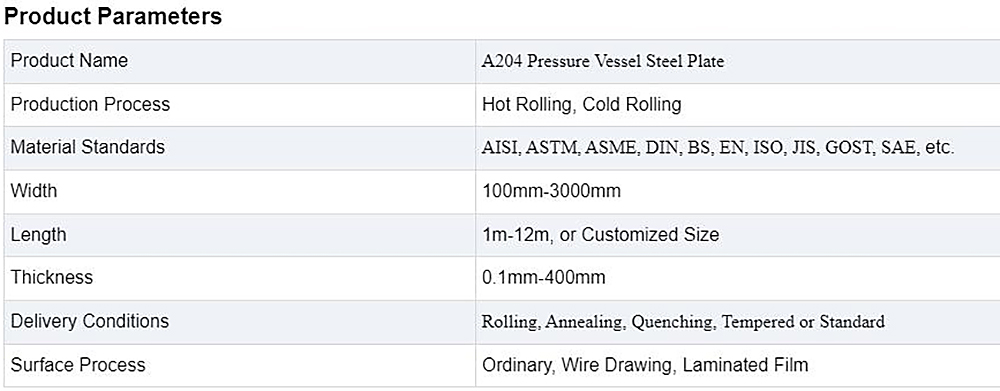

A204 Pressure Vessel Steel Plate

ASTM A204 boiler vessel plate is molybdenum alloy steel plate, mainly suitable for welding boilers and high temperature pressure vessels.

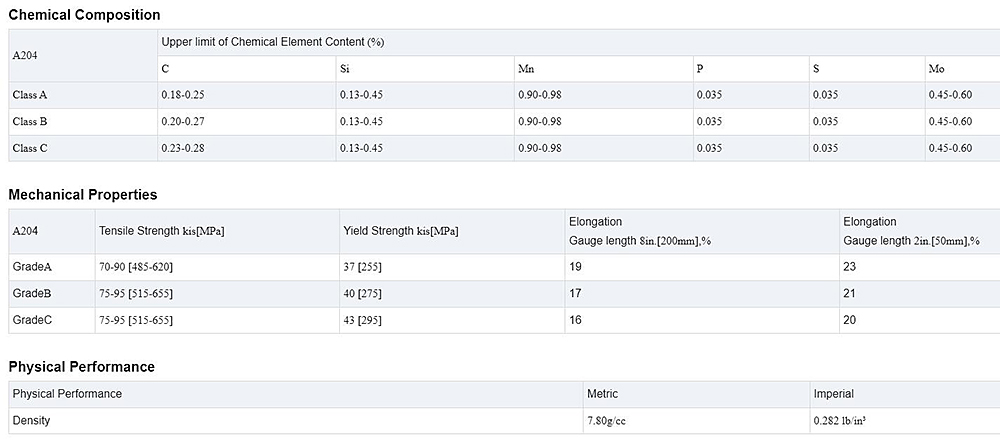

A204 Pressure Vessel Steel Plate Description

According to the molybdenum content, ASTM A204 boiler vessel plate is divided into 3 grades: A, B, C. The thickness of ASTM A204 boiler vessel plates is limited only by the ability of the chemical composition to meet the specified mechanical property requirements. ASTM A204 boiler vessel plates are widely used in petroleum, chemical industry, power station, boiler and other industries, particularly in the manufacture of reactors, heat exchangers, separators, spherical tanks, liquefied gas, nuclear reactor pressure vessels, boiler drum steam, liquefied petroleum gas, hydropower stations, high pressure pipelines, etc.

Product Parameters

ASTM A204 boiler vessel plate is widely used in petroleum, chemical industry, power station, boiler and other industries, used in the manufacture of reactors, heat exchangers, separators, spherical tanks, liquefied gas, nuclear reactor pressure vessels, boiler drum steam, liquefied petroleum gas, hydropower stations, high pressure pipelines, etc.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)