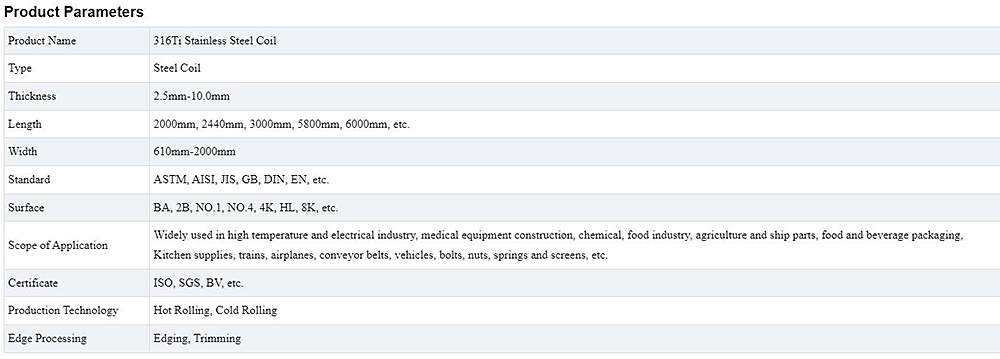

316Ti Stainless Steel Coil

316Ti is a titanium stabilized version of 316 molybdenum-containing austenitic stainless steel. It is more resistant to general corrosion and pitting/crevice corrosion than traditional chromium-nickel austenitic stainless steels such as 304.

Details

Stainless Steel Coil:

Stainless steel coils can be divided into austenitic stainless steel, ferritic stainless steel,martensitic stainless steel, duplex stainless steel, etc. The most common ones are 201,201L,301,304,304L,316,316L, 409 etc.

316Ti Stainless Steel Coil

316Ti is a titanium stabilized version of 316 molybdenum-containing austenitic stainless steel. It is more resistant to general corrosion and pitting/crevice corrosion than traditional chromium-nickel austenitic stainless steels such as 304.

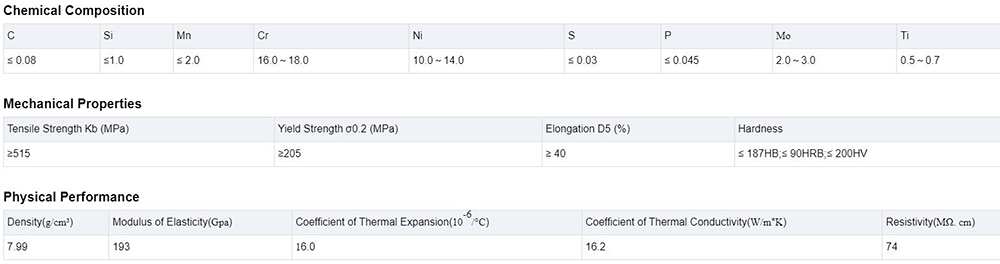

316Ti Stainless Steel Coil Description

316Ti stainless steel comes with superior corrosion resistance in various corrosive media such as acids, alkalis, and salts. This is because it contains high chromium and nickel content, and an appropriate amount of titanium is added to the steel to improve corrosion resistance by forming a stable passivation film. 316Ti stainless steel has good processing properties, such as weldability, bending formability and machining performance. This facilitates easy processing and connection during the manufacturing process, adding to production efficiency. What is more, 316Ti stainless steel coil can still keep good strength and stability at high temperatures and can be used in the temperature range of -253°C to 400°C. This makes it widely used in high-temperature environments.

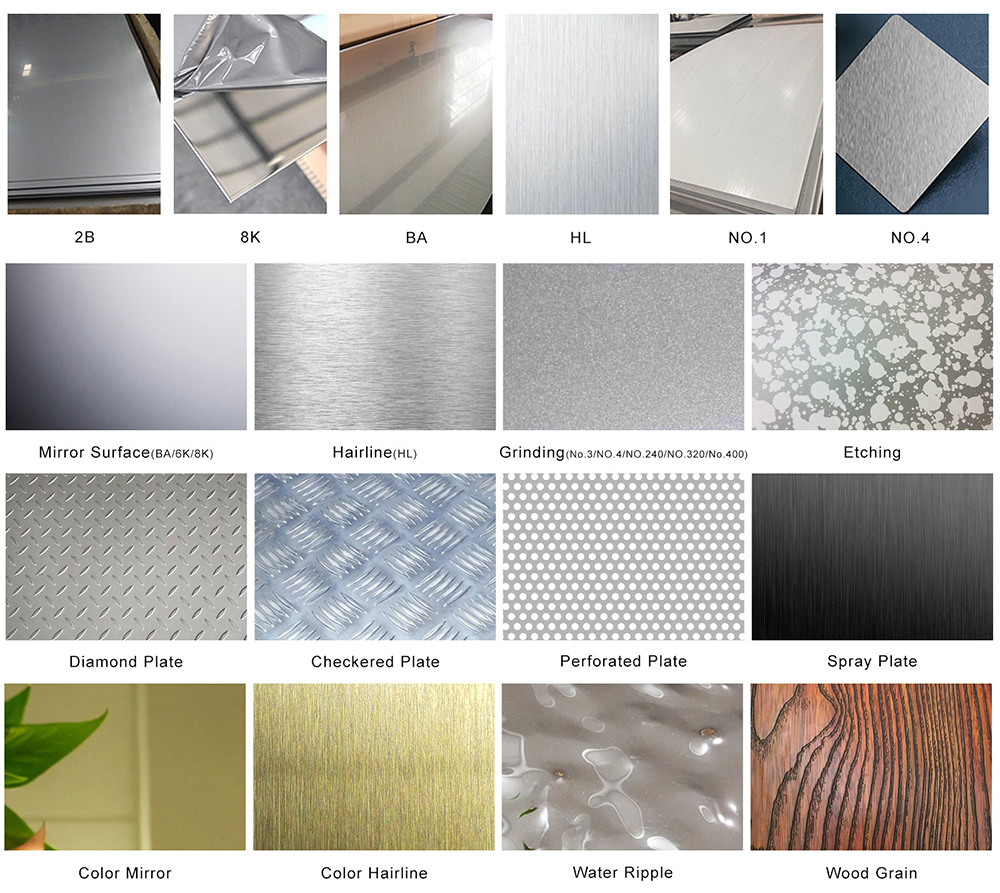

Surface Selection

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)