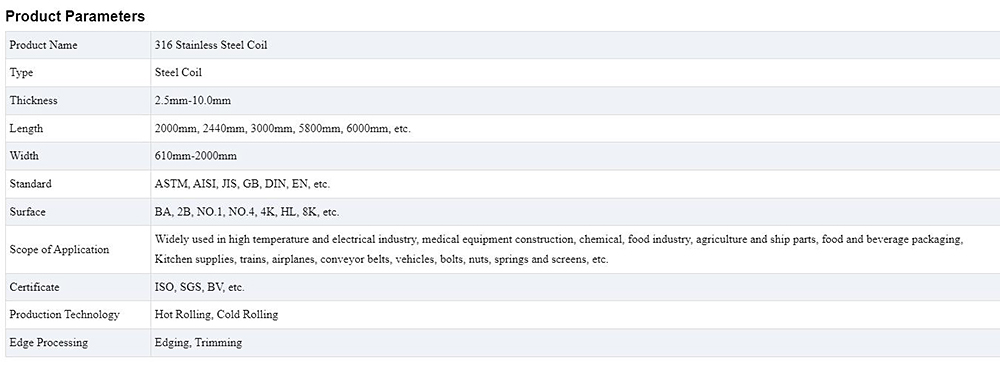

316 Stainless Steel Coil

316 stainless steel also contains 2-3% molybdenum, in addition to iron, chromium and nickel. The addition of molybdenum significantly improves the performance of 316 stainless steel in certain corrosive environments, especially those containing chlorides. 316 stainless steel is more commonly used in situations requiring higher corrosion resistance.

Details

Stainless Steel Coil:

Stainless steel coils can be divided into austenitic stainless steel, ferritic stainless steel,martensitic stainless steel, duplex stainless steel, etc. The most common ones are 201,201L,301,304,304L,316,316L, 409 etc.

304 Stainless Steel Coil

304 stainless steel is a superior material with regard to corrosion resistance, heat resistance, low temperature strength and mechanical properties, as one of the most widely used types of stainless steel. In addition, it has exceptional hot-workability such as stamping and bending, without leaving heat treatment hardening phenomenon.

316 Stainless Steel Coil Description

316 stainless steel coil is an ideal option in the stainless industry for a number of key reasons. Grade 316 is the standard molybdenum-bearing austenitic grade, which is highly resistant to pitting and crevice corrosion in chloride environments. So 316 stainless steel is more commonly used in situations where higher corrosion resistance is needed. For example, in marine engineering, 316 stainless steel is often used to manufacture ship parts, subsea pipelines, offshore platforms and other facilities. In the chemical industry, it is also commonly used to manufacture equipment such as storage tanks, reactors and pipelines. In addition, in the medical field, 316 stainless steel is also widely used to manufacture medical devices and implants due to its excellent biocompatibility and corrosion resistance.

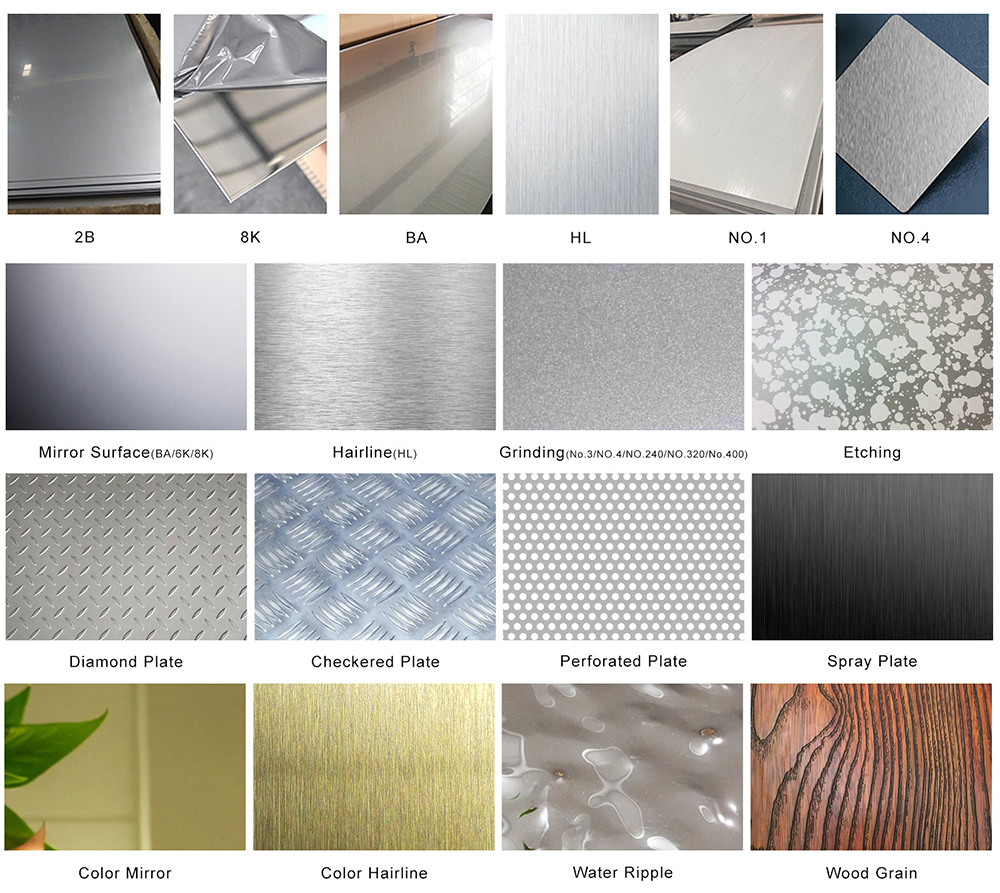

Surface Selection

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)