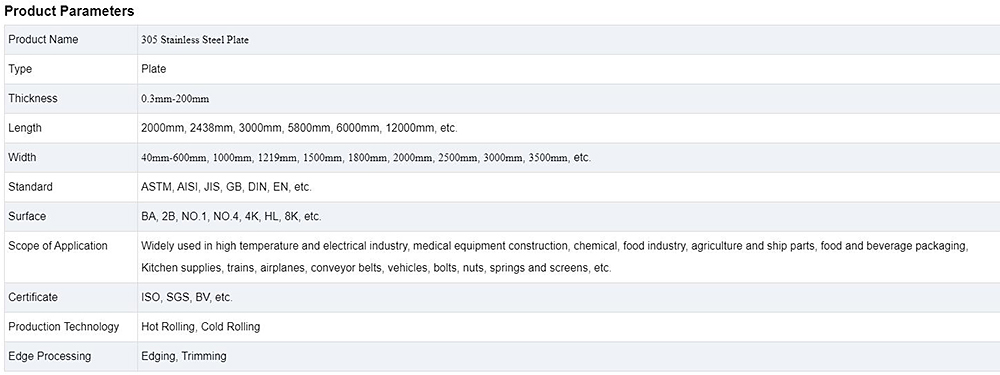

305 Stainless Steel Plate

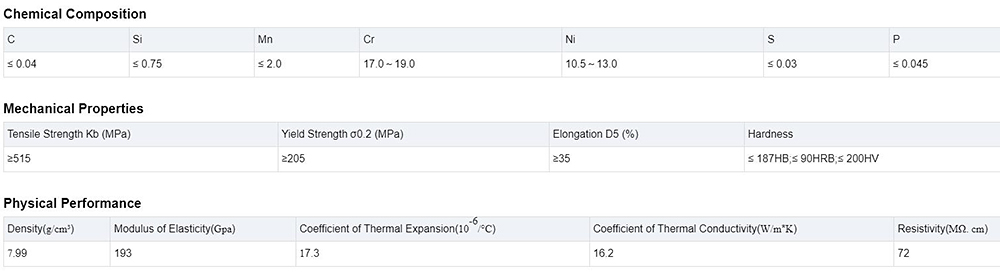

305 stainless steel is a common austenitic stainless steel containing elements such as chromium, nickel, and manganese. Chromium is the main anti-corrosion element and can combine with oxygen to form a dense oxide film to protect materials from corrosion. Nickel can improve the material's heat resistance and toughness while reducing its magnetism. Manganese can increase the strength and hardness of

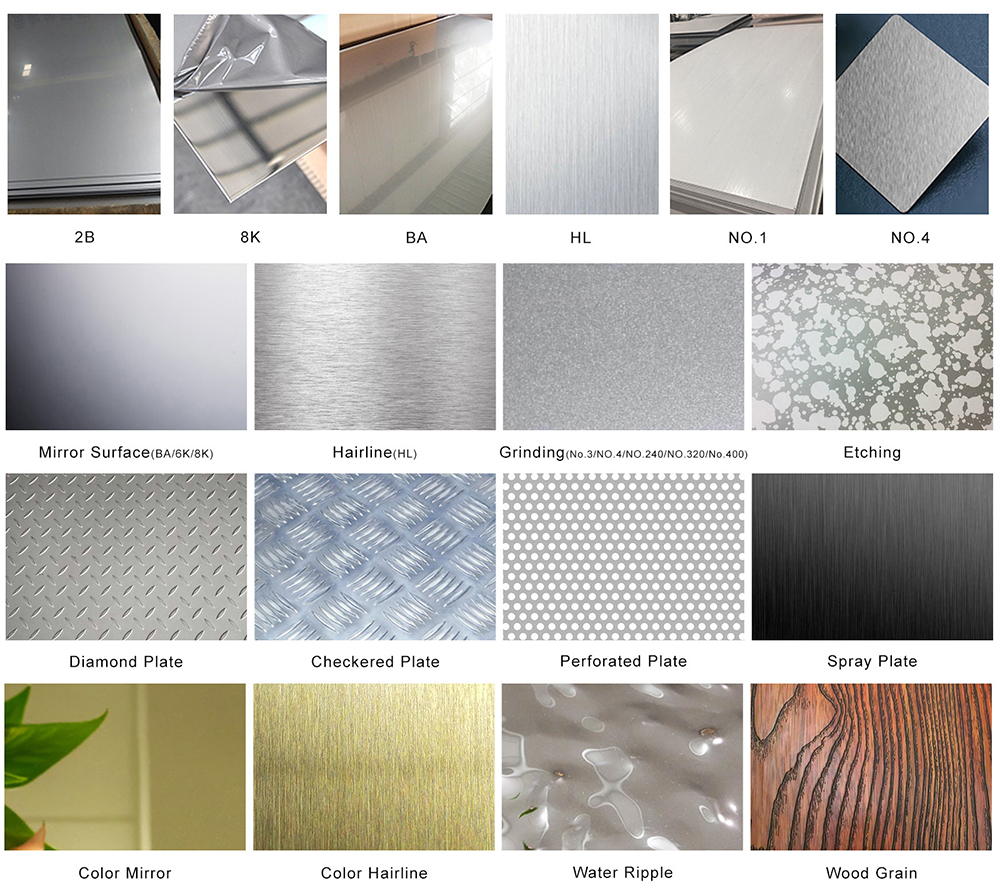

Details

Stainless Steel Plate:

Stainless steel plates can be divided into austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, duplex stainless steel, etc. The most common ones are 201, 201L,301,304,304L,316,316L,409 etc

304 Stainless Steel Plate

304 stainless steel highly stands out in terms of corrosion resistance, heat resistance, low temperature strength and mechanical properties, being one of the most widely used types of stainless steel. In addition, it has exceptional hot-workability such as stamping and bending, without leaving heat treatment hardening phenomenon.

305 Stainless Steel Plate Description

305 stainless steel has good corrosion resistance and can remain stable in various corrosive media. The oxide film formed on its surface can effectively prevent the contact between the corrosive medium and the material, thereby extending the service life of the material. 305 stainless steel has good heat resistance and can maintain stable performance at high temperatures. Its high content of nickel element can improve the heat resistance of the material, making it less likely to deform, oxidize or fail at high temperatures. In addition, it has high strength and hardness and can withstand greater pressure and impact. Its high content of manganese element can improve the strength and hardness of the material, making it less likely to deform or break when under pressure. 305 stainless steel is often used in the chemical industry, food processing, construction, aerospace, marine engineering, and other fields.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)